Why and when to use finned tubes

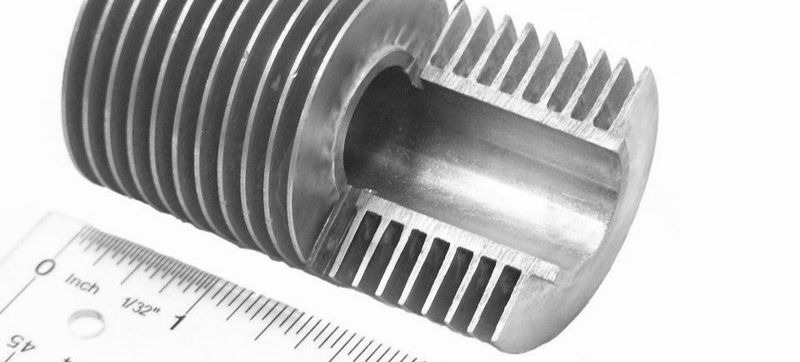

First of all, the main purpose of using finned tubes is to provide an increase in surface on the side where the fluid offers more thermal resistance, aiming to make worth the better potential to heat transfer of the oposite fluid.

That means that it is not worth to increase the surface by fins on one side of the heat exchanger if the fluid at the opposite side is also poor in capacity of heat transfer.

The capacity of heat transfer is expressed as a coefficient that rates the amount of heat that can be transferred per area unity for a given temperature gradient.

Let us say that one fluid can transfer a rate of 1.000 kcal/h per square meter for a given temperature gradient (from the fluid to the wall that separates both fluids) while the second fluid can transfer only 50 kcal/h.

So, 1 square meter of surface will allow the exchange of a maximum of 50 kcal/h in the situation and the great potential of the first fluid is worthless.

But, if for each square meter on the side of the first fluid we provide 20 square meters on the side of the second fluid, now we can transfer 1.000 kcal/h. This is exactly what fins do.

INTHEATEX offers a sofware package for the most common applications of finned tube heat exchangers